Ready to dive into RFID for your business? Whether you’re tracking inventory, tools, or assets, choosing the right RFID tags and equipment can make or break your setup. Before buying RFID tags, first, you need to know whether you have done a good RFID system, RFID tag chip type, whether your use of the environment has metal and moisture, whether you need to be resistant to high temperatures, what is the sensing distance you need, etc. Then you can find the right RFID tags for you faster.

What Is RFID and Why Invest in It?

RFID uses radio waves to track assets via tags and readers. Tags store data (like IDs or locations), and readers capture it for real-time tracking. Unlike barcodes, RFID scans multiple items instantly without line-of-sight, making it ideal for warehouses, retail, or healthcare. Investing in RFID boosts inventory accuracy to 95–99%, cuts audit times by up to 80%, and reduces losses. Whether you’re a small business or a large enterprise, the right RFID setup can save money and streamline operations, but it starts with choosing the right equipment.

Types of RFID Tags: Passive vs. Active

Choosing tags is step one. Here’s the breakdown:

- Passive Tags: No battery, powered by readers. They’re affordable ($0.08–$2 each), compact, and great for inventory or retail stock. Read range is shorter (up to 10 meters).

- Active Tags: Battery-powered, with longer ranges (up to 100 meters). Costlier ($5–$50), but ideal for tracking high-value assets like vehicles or medical equipment in real time. Pick passive for cost-effective, high-volume tracking; go active for dynamic, long-range needs like logistics or large facilities.

Types of RFID Readers

Readers capture tag data, and you’ve got options:

- Handheld Readers: Portable, great for mobile scanning in warehouses or retail. Prices range from $500–$2,000. Example: Zebra’s MC3330xR.

- Fixed Readers: Installed at entry points like doors for automatic scanning. Cost $1,000–$5,000 but ideal for high-traffic areas. Example: Impinj Speedway.

- USB Readers: Budget-friendly ($100–$500) for small-scale use, like desk-based tag programming.

- Mobile Device Add-Ons: Attach to smartphones for flexibility. Best for small businesses or field operations. Choose based on your environment—handhelds for flexibility, fixed for automation.

Key Factors to Consider When Buying RFID Tags

Not all tags are created equal. Keep these in mind:

- Frequency:

- Low Frequency (LF, 125–134 kHz): Short range (up to 1 meter), good for animal tracking or access control.

- High Frequency (HF, 13.56 MHz): Medium range (up to 1.5 meters), used for payment systems or library books.

- Ultra-High Frequency (UHF, 860–960 MHz): Long range (up to 15 meters), perfect for inventory or supply chains.

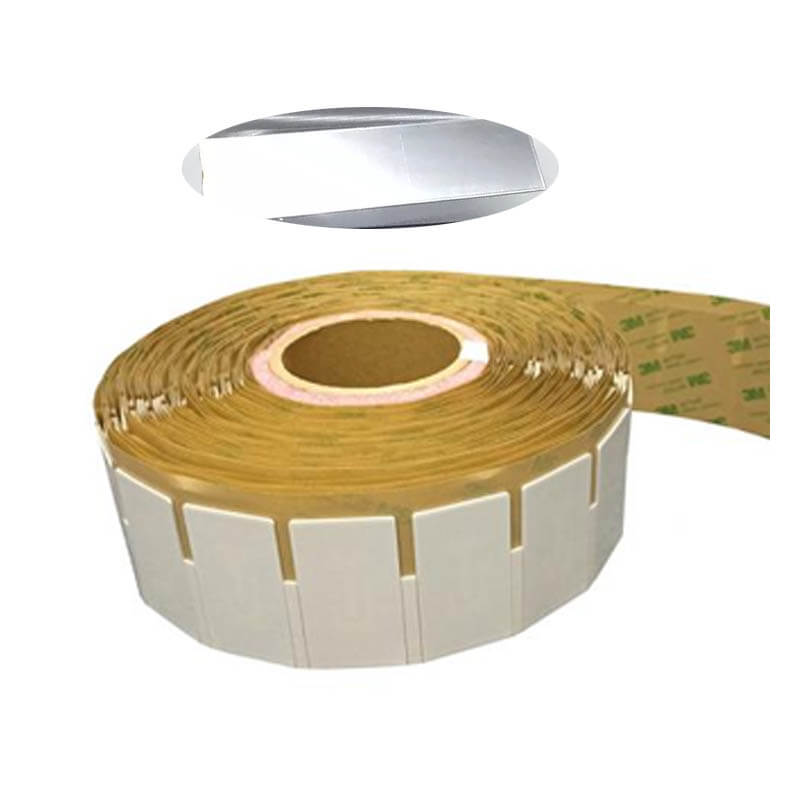

- Environment: Metal or liquid can interfere. Use on-metal tags (like HID’s IQ On-Metal) for tough settings.

- Durability: For harsh conditions (e.g., outdoor or industrial), choose rugged tags with IP68 ratings.

- Memory: Basic tags store IDs; advanced ones hold more data (e.g., maintenance history). Match tag specs to your use case—UHF for warehouses, HF for secure payments.

Choosing the Right RFID Reader

Your reader choice depends on your setup:

- Read Range: Match the reader’s range to your tags (e.g., UHF readers for UHF tags).

- Connectivity: Ensure compatibility with your software (Wi-Fi, Bluetooth, or Ethernet).

- Portability: Handhelds for manual scans; fixed for automated tracking at choke points.

- Durability: Industrial environments need rugged readers with IP65+ ratings. Test readers in your environment—Atlas RFID Store offers demos to ensure compatibility.

Software: The Brains of Your RFID System

RFID software turns raw data into insights. Look for:

- Integration: Syncs with ERP or inventory systems like SAP or QuickBooks.

- Features: Real-time tracking, analytics, or maintenance scheduling.

- Ease of Use: User-friendly dashboards for quick adoption. Providers like Asset Infinity or TagMatiks offer cloud-based platforms that scale. Test software with a free trial to ensure it fits your workflow.

Cost Breakdown: What to Expect

RFID costs vary by scale:

- Tags: Passive tags start at $0.08; active tags range from $5–$50.

- Readers: USB readers ($100–$500), handhelds ($500–$2,000), fixed readers ($1,000–$5,000).

- Software: $500–$5,000 for licenses, or $50–$200/month for cloud subscriptions.

- Setup: Installation and integration can add $1,000–$10,000 for large systems. Start small with passive tags and a handheld reader to keep costs low, then scale as needed.

Steps to Buy the Right RFID System

Follow these steps for a smart purchase:

- Define Your Needs: Are you tracking inventory, tools, or vehicles? Set goals like reducing losses or speeding audits.

- Assess Your Environment: Metal, water, or distance affects tag and reader choice.

- Choose Frequency: UHF for long-range, HF for secure applications, LF for niche uses.

- Pick Tags and Readers: Match specs to your needs. Test samples from suppliers like Atlas RFID Store.

- Select Software: Ensure it integrates with your systems and offers analytics.

- Budget Wisely: Start with a pilot to test ROI before going all-in.

- Partner with Experts: Vendors like HID Global or Atlas RFID Store offer consultations to guide you.

Common Mistakes to Avoid

Don’t trip up! Watch out for:

- Wrong Frequency: Mismatched tags and readers (e.g., UHF tags with HF readers) won’t work.

- Ignoring Environment: Standard tags fail on metal or in wet conditions. Choose specialized tags.

- Skimping on Software: Cheap software may lack integration or analytics features.

- No Testing: Always test tags and readers in your setting before buying in bulk. Request samples or demos from suppliers to avoid costly missteps.

Where to Buy RFID Tags and Equipment

Trusted vendors include:

- Atlas RFID Store: Wide range of tags, readers, and expert support. Offers samples and demos.

- HID Global: Specializes in durable tags for tough environments, like on-metal or high-temperature.

- Asset Infinity: Bundles tags, readers, and software with strong integration options.

- Impinj: Known for high-performance UHF readers and tags. Shop around, compare prices, and check reviews. Many vendors offer free consultations or trials.

- WXR: The best manufacturers of RFID tags, RFID cards, and RFID wristbands in China.

FAQs About Buying RFID Tags and Equipment

Q: How many tags do I need?

A: Depends on your assets. Start with 100–1,000 for a pilot, then scale up.

Q: Can I use RFID tags on metal?

A: Yes, use on-metal tags like HID’s IQ series for reliable performance.

Q: Are cheap tags worth it?

A: Low-cost passive tags work for basic tracking but may lack durability for harsh environments.

Q: How do I know if a reader suits my needs?

A: Test it in your environment. Vendors like Atlas RFID Store offer demos.

Get Started with Your RFID Purchase

Buying RFID tags and equipment doesn’t have to be daunting. By matching tags, readers, and software to your needs, you can unlock real-time tracking, 95%+ accuracy, and huge time savings. Start with a small pilot, test with trusted vendors like Atlas RFID Store or HID Global, and scale as you see results. Ready to revolutionize your asset tracking? Reach out to an RFID expert for a free consultation and make your first purchase a smart one!

Related articles:

- Unique Features and Benefits of Custom RFID Tags

- 6 Crucial Factors that Affect RFID Read Range – A Detailed Guide

- RFID vs. NFC: What’s the difference between them?

- LF, HF, and UHF Frequency: What’s the Difference?

- What Are RFID Tags and How Are They Used?

- A Guide to RFID Tags Types And What are they Difference